I’m building a set of driveway gates, each leaf is 1600mm wide by 2m tall.

I have made the frame from 4x2 PSE, with a mid rail, which gives me two panels to drop some match boarding into. These panels are around 1400x825mm.

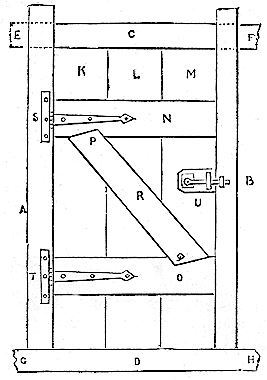

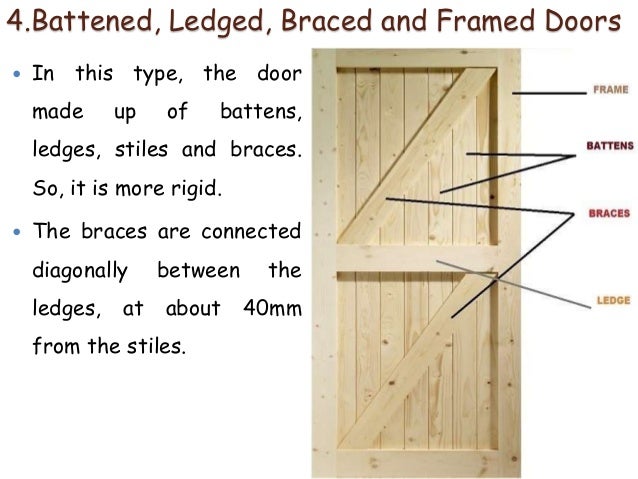

I intended to add some bracing around 45 degrees, but it looks wrong.

Would it be stronger to make two upward pointing chevrons or will a single brace per panel be acceptable? If so what angles should I be going for.

The rails have straight through tenons with wedges.

Tia.

I have made the frame from 4x2 PSE, with a mid rail, which gives me two panels to drop some match boarding into. These panels are around 1400x825mm.

I intended to add some bracing around 45 degrees, but it looks wrong.

Would it be stronger to make two upward pointing chevrons or will a single brace per panel be acceptable? If so what angles should I be going for.

The rails have straight through tenons with wedges.

Tia.