Underway on a T&G ceiling cladding on 25mm wood.

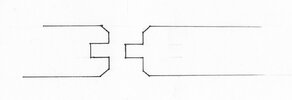

The wood has a V profile, (as per sketch)

I could have clad in just straight runs .. but chose to have a bit more 'show' about it.

Due to layout there are corner sections at 45 degree and horizontal runs to but against them.

Sketch (rough) of the corner and runs.

The first 4 or maybe 5 lengths will need to mate with the male profile of the last corner board.

Can you get a 'reasonably' priced router bit to do this profile in one pass (I have a table mounted 1/2" router)

I can do this with multiple passes with separate bits, but having to keep changing bits for rebate, and the 45 degree is going to be a pain on each piece and likely to introduce errors.

.

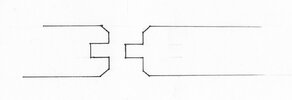

The wood has a V profile, (as per sketch)

I could have clad in just straight runs .. but chose to have a bit more 'show' about it.

Due to layout there are corner sections at 45 degree and horizontal runs to but against them.

Sketch (rough) of the corner and runs.

The first 4 or maybe 5 lengths will need to mate with the male profile of the last corner board.

Can you get a 'reasonably' priced router bit to do this profile in one pass (I have a table mounted 1/2" router)

I can do this with multiple passes with separate bits, but having to keep changing bits for rebate, and the 45 degree is going to be a pain on each piece and likely to introduce errors.

.