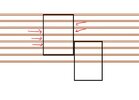

For fixing 18mm plywood sheets over the joists, I am thinking of using 4.5 x 60mm or 4.5 x 70mm ?

Like these

or

Or do I need 5x90mm like these

I do not know what is more appropriate,

Like these

Screw-Tite PZ Countersunk Screws 4.5 x 60mm 200 Pack

Order online at Screwfix.com. Tri-Lock TS threadform, PZ recess, high performance, multipurpose screw. FREE next day delivery available, free collection in 5 minutes.

www.screwfix.com

or

Timco Velocity PZ Countersunk Multi-Use Screws 4.5 x 70mm 200 Pack

Order online at Screwfix.com. Premium countersunk screws, with twisted shank and low friction coating for rapid drive-in. Suitable for use in thin sheet metal, PVCu, MDF, chipboard, softwood and hardwood. FREE next day delivery available, free collection in 5 minutes.

www.screwfix.com

Or do I need 5x90mm like these

Timco C2 Strong-Fix PZ Countersunk Multipurpose Premium Screws 5.0 x 90mm 325 Pack

Order online at Screwfix.com. Multi-material screw with twin-cut technology. Ideal for applications when optimum holding force is required, such as hinges, brackets and high load environments. Features deep recess to prevent cam-out, giving precise and positive drive control. Under-head ribs...

www.screwfix.com

I do not know what is more appropriate,