D

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Floating oak mantle

- Thread starter VioletG

- Start date

Juast to be clear, do you mean Rawlbolts (steel shield anchors)

View attachment 254666

or Rawlplugs (lightweight plastic plugs)?

View attachment 254667

And what type of composition is the wall - brick, blockwork (light or heavy), etc

Thanks.

The wall is brick, it's a 1930's brick fireplace.

I was thinking of rawlplugs as that is what place likes Celtic timber have in their videos. The issue is they don't specify the beam size in regards to the best fixing.

French cleat, every time

That sounds really complicated for someone like myself.

Lol. It's simple. It's a couple of blocks of wood or metal hooks.

Use the principle, you don't have to make it complicated.

No metal bars to worry about setting perfectly and aligning perfectly or to bend afterwards.

Use the principle, you don't have to make it complicated.

No metal bars to worry about setting perfectly and aligning perfectly or to bend afterwards.

The metal ones are used to hang your kitchen cupboards and come individually or as a rail, the latter being easier to get level for the beginner.That sounds really complicated for someone like myself.

hanging brackets for kitchen cabinets | eBay

Blup

To keep your threaded rods in place and an even height get a piece of wood of a suitable length drill holes in it that match where the threaded rods go, drill an extra couple of small holes and use rawl plugs and screws to secure the wood to the wall whilst the resin goes off.

Lol. It's simple. It's a couple of blocks of wood or metal hooks.

Use the principle, you don't have to make it complicated.

No metal bars to worry about setting perfectly and aligning perfectly or to bend afterwards.

The metal ones are used to hang your kitchen cupboards and come individually or as a rail, the latter being easier to get level for the beginner.

hanging brackets for kitchen cabinets | eBay

Blup

Are they something like this that I had on my old shelf.

To keep your threaded rods in place and an even height get a piece of wood of a suitable length drill holes in it that match where the threaded rods go, drill an extra couple of small holes and use rawl plugs and screws to secure the wood to the wall whilst the resin goes off.

That makes sense, thanks.

Are they something like this that I had on my old shelf.

Yes looks like it, but it says made in England, so maybe time for some newer ones as per the link put up.

Blup

I just used a couple of steel perforated plates down the back of mine , screwed to rear of timber and recessed about 80mm above the timber into plaster and fixed with a couple of screws . My oak is about 6” deep x 10” and 50” long.

Only leaves a few square inches to be filled and made good , may be difficult to see behind decorations .

Only leaves a few square inches to be filled and made good , may be difficult to see behind decorations .

D

Deleted member 174758

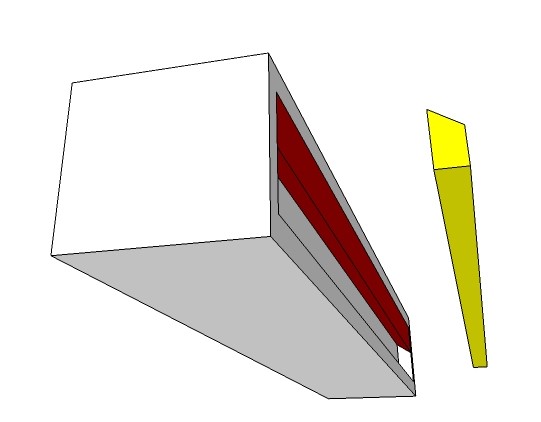

Hopefully this will explain what the problems are in doing this with a French cleat (an American term, or in English terms a "split batten"). A split batten is made by bevel rip sawing a wider piece of timber, sau a 3 x 1in planed piece to produce two pieces with an angled meeting face:

You can purchase ready-made split battens from some trade timber merchants, but by no means all. I generally prpare my own on site with a portable table saw - this is not really a job for a hand held saw (not accurate enough). Obviously this needs a certain depth to accommodate the split batten, so if the item is less than about 70mm deep (110mm with a recessed split batten - see below) it just won't work.

The piece in red is screwed to the rear of the panel or item you want to hand on the wall, the other piece (coloured yellow) is fixed to the wall. The problem is that these will jack the item off the wall by the thickness of the cleat (generally 20 to 22mm as they finish at that size when the timber is planed). Normally when we are using these it is to hang flat panels, such as removeable fascia panels, wall cabinets or T-slot boards (think about the sort of slot walling you see in shops) so the top and bottom edges won't be visible, meaning that this offset isn't an issue. You generally suspend panels on two or more parallel split battens to allow you to plumb up the pnels.

The other issue with split battens is the the wall they are going onto has to be dead flat side to side, which of course walls never are. If the walls aren't dead flat the batten on the wall will conform to the wall and you'll struggle to get the piece to hand on the wall - so you end up using a long straight edge (such as a long spirit level) to allow you to check whilst you pack the batten off the wall to make it flat.

The problem, as I said is that split battens jack the item off the wall, so if you want the item to site flush against the wall you need to recess the the battens into the back of the mantle piece with a router - a lot of work. The same goes for the slimline metal split batten used in shop fitting - these are shallower (about 4mm), but still require recessing (and they are very sensitive to the flatness of the wall they are going onto) - so unless you recess them (as the OPs photo clearly shows) the mantle you are hanging will not pull flush into the wall

Above: This cleat is clearly recessed in a rebate to make the connection to the wall flat

There are other issues with using cleats in this case, but hopefiully this explains why they should be discounted. Split battens have their uses - just not here. Resin anchors are actually way easier to get right IMHO

You can purchase ready-made split battens from some trade timber merchants, but by no means all. I generally prpare my own on site with a portable table saw - this is not really a job for a hand held saw (not accurate enough). Obviously this needs a certain depth to accommodate the split batten, so if the item is less than about 70mm deep (110mm with a recessed split batten - see below) it just won't work.

The piece in red is screwed to the rear of the panel or item you want to hand on the wall, the other piece (coloured yellow) is fixed to the wall. The problem is that these will jack the item off the wall by the thickness of the cleat (generally 20 to 22mm as they finish at that size when the timber is planed). Normally when we are using these it is to hang flat panels, such as removeable fascia panels, wall cabinets or T-slot boards (think about the sort of slot walling you see in shops) so the top and bottom edges won't be visible, meaning that this offset isn't an issue. You generally suspend panels on two or more parallel split battens to allow you to plumb up the pnels.

The other issue with split battens is the the wall they are going onto has to be dead flat side to side, which of course walls never are. If the walls aren't dead flat the batten on the wall will conform to the wall and you'll struggle to get the piece to hand on the wall - so you end up using a long straight edge (such as a long spirit level) to allow you to check whilst you pack the batten off the wall to make it flat.

The problem, as I said is that split battens jack the item off the wall, so if you want the item to site flush against the wall you need to recess the the battens into the back of the mantle piece with a router - a lot of work. The same goes for the slimline metal split batten used in shop fitting - these are shallower (about 4mm), but still require recessing (and they are very sensitive to the flatness of the wall they are going onto) - so unless you recess them (as the OPs photo clearly shows) the mantle you are hanging will not pull flush into the wall

Above: This cleat is clearly recessed in a rebate to make the connection to the wall flat

There are other issues with using cleats in this case, but hopefiully this explains why they should be discounted. Split battens have their uses - just not here. Resin anchors are actually way easier to get right IMHO

Last edited by a moderator:

recess them (as the OPs photo clearly shows) the mantle you are hanging will not pull flush into the wall

That's more or less what I'd do (and have done), but not necessarily all the way across. It could be just two pockets one at each end, or the same principle with a metal clip recessed

What this concept does is pull the mantle tight against the wall naturally. The rod idea does not, and there is more messing about to get right/aligned and secure it tight afterwards

D

Deleted member 174758

Only if you (i) recess the cleats into the back of the mantel and (ii) ensure that the cleat on the wall is dead straight. I've done enough split battens to know that!What this concept does is pull the mantle tight against the wall naturally. The rod idea does not, and there is more messing about to get right/aligned and secure it tight afterwards

There are lots of "only ifs" with the rod or other methods.Only if you (i) recess the cleats into the back of the mantel and (ii) ensure that the cleat on the wall is dead straight. I've done enough split battens to know that!

This cleat principle is the best option.

A small cleat can be made to self level and align.

There are lots of "only ifs" with the rod or other methods.

This cleat principle is the best option.

A small cleat can be made to self level and align.

Perhaps but unless the shelf is super thick there remains the risk of someone accidentally knocking it off.

Cleats are great for 4 foot tall headboards but I am not sure that they are ideal in this situation.

/justSayin