I have some engineering wood floor from Wickes; it's the click type mechanism, that I'll install in my downstairs living room

I have the same floor upstairs over fibre underlay and despite having levelled the subfloor and glued the click joints with PVA, it still has the odd creak when stepping over it in some places. This particular click mechanism is bad, some friends have the same and it creaks like hell (they didn't glue the joints); some other have bought a cheap laminate and not even bothered levelling the subfloor, no creaks.

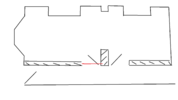

I was then thinking about glueing it directly to the concrete subfloor as it's typically done for non-click floors. I know I paid a premium for the click mechanism but I don't care too much. What glue is best?

I have the same floor upstairs over fibre underlay and despite having levelled the subfloor and glued the click joints with PVA, it still has the odd creak when stepping over it in some places. This particular click mechanism is bad, some friends have the same and it creaks like hell (they didn't glue the joints); some other have bought a cheap laminate and not even bothered levelling the subfloor, no creaks.

I was then thinking about glueing it directly to the concrete subfloor as it's typically done for non-click floors. I know I paid a premium for the click mechanism but I don't care too much. What glue is best?