Got like for like replacement, so now the question is closed, crossing fingers I have done the right thing, a heat pump dryer is a condensing dryer, there are three ways to get a cool surface for the moisture to condense out of the circulating air, one is a water cooled condenser, wastes water, but is compact and used with many washer/driers, second is air in the room, this will warm the room, so depends on how big the room is, and the third is refrigeration (heat pump) main draw back is room must not be under a set temperature often 5°C or the moisture will freeze on the condenser.

Because the room used is small and not using a washer/drier, and not hole for vented the heat pump does seem best option, and on swapping from vented 1000 watt to heat pump the current used dropped by half, and the time was around the same, as time went on it was using more and more power to dry the clothes until it finally stopped.

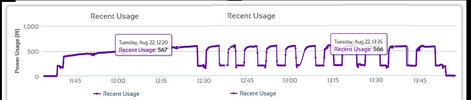

When we first got the heat pump drier we did use an energy meter, but once it showed it was working well stopped using it. It was not easy to see what was going on, these two graphs

done when the failed drier was new, The mark/space is keeping the maximum temperature down to some pre-set figure, and one would have thought this showed working OK, but got the same mark/space ratio with the failed machine. The estimated time to dry also did not seem to alter, but before complete failure the actually time was getting longer and longer although estimated time stayed the same.