Hi all

I want to make an outside table like the one in the pic below

I'm going to use 8x2 boards.

The legs i can buy ready made online for £60.

The table costs around £500 but I can do it for a fraction of that.....

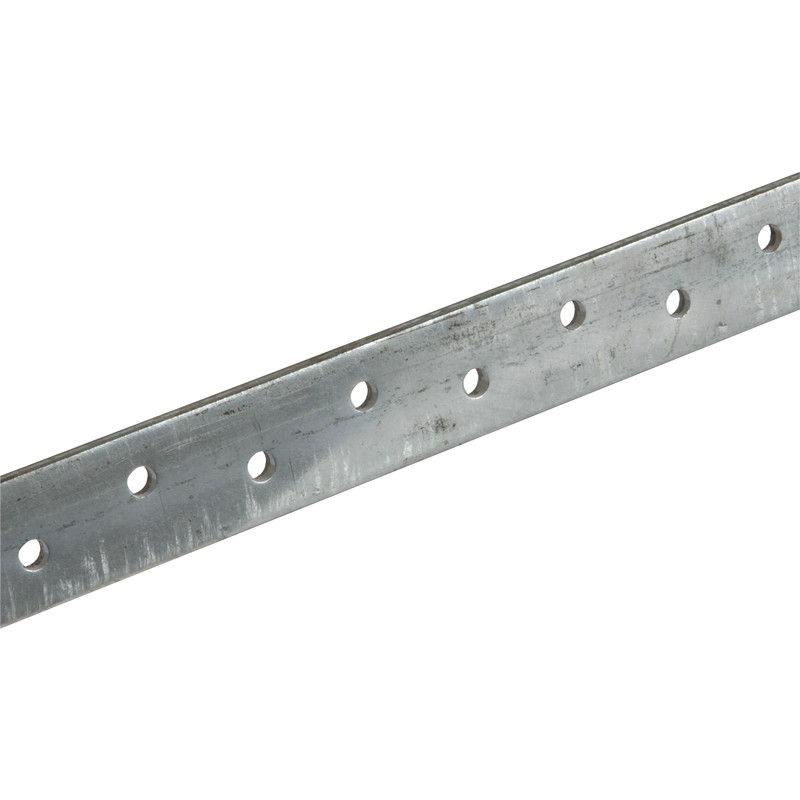

However my only issue is that I'm not sure how to stop the wood from twisting. If it will twist.

Any tips

I want to make an outside table like the one in the pic below

I'm going to use 8x2 boards.

The legs i can buy ready made online for £60.

The table costs around £500 but I can do it for a fraction of that.....

However my only issue is that I'm not sure how to stop the wood from twisting. If it will twist.

Any tips