- Joined

- 7 Feb 2018

- Messages

- 144

- Reaction score

- 12

- Country

Hello

My parents have a few acres in France and I've ran out of activities to do outside of drinking the local wine - its Lot-et-Garrone region which is all thick full bodied Bordeaux style and I can't handle it any more.

So they also have an oak forest intruding onto the property meaning there is plenty of 10+"diameter x 40 foot oaks ion the garden, and most of them are nicely straight & true.

So I decided to make something from oak, something like a gable end garage a bit like this:

As usual with any of my projects I set about doing the whole thing completely free, as, being an engineer, I refuse to pay for engineering services by others.. (mostly)

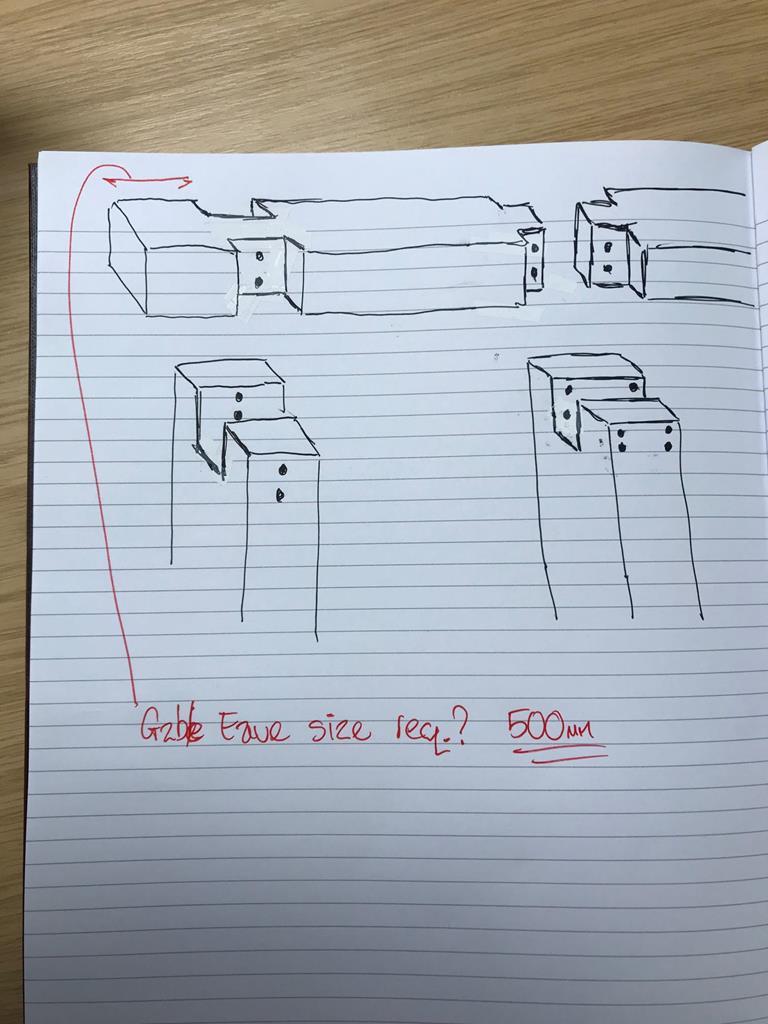

Did some working out of materials and sizes:

Decided the joints where 3-4 beams converge was not practical with my skill, so figured out a work around using simple steel designs

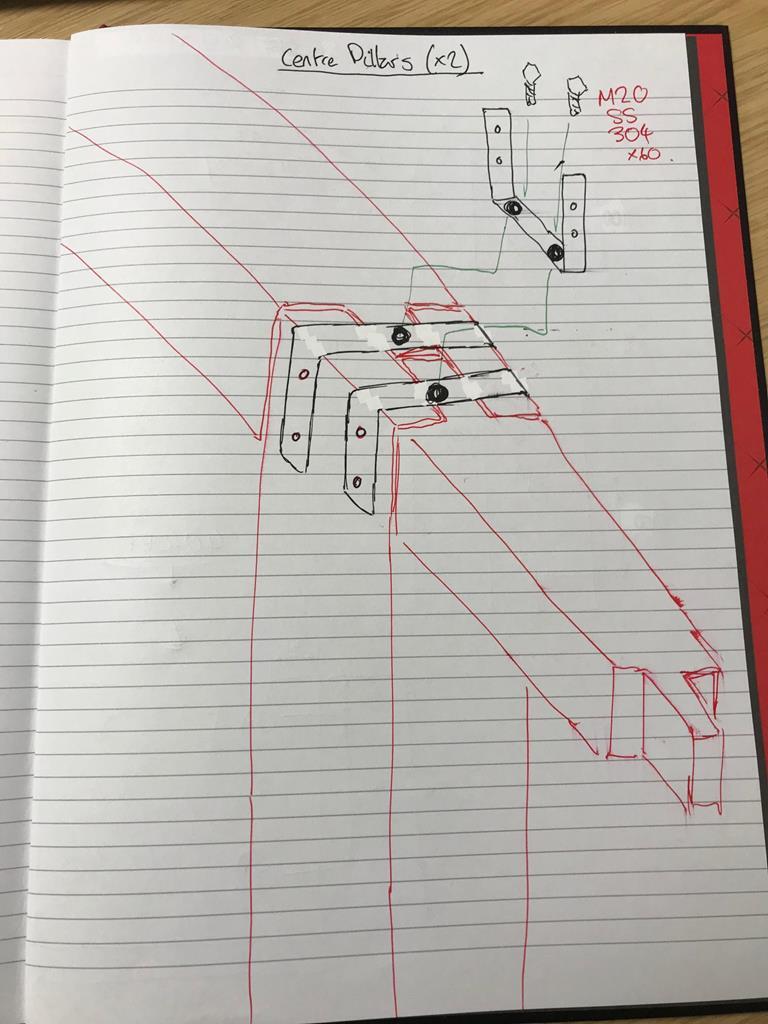

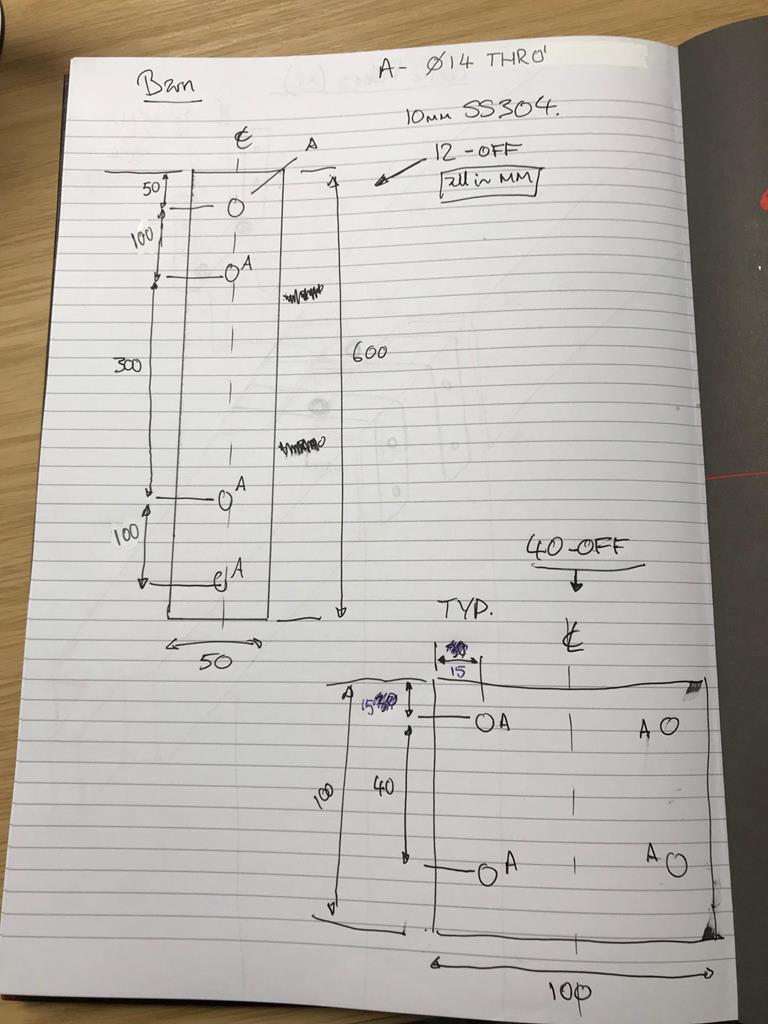

Bit more detail design;

Thinking all the steel will be premade in UK and shipped over, so figured just make one size of strapping and pack the smaller beams to suit

Basically decided to copy the roman wash house down the road because it looks nice. We are also near a 14th century church and to comply with / and achieve any kind of consent, any new building needs to look like it basically, and as I will be building a 'wood store' first (no walls), then go down the retrospective planning route and asking for permission to wall it in, as we assume the local council will actually be impressed by it..

After reading in to what's easiest and/or best to do for foundations (strip or raft), I decided to go for pad foundations... As I decided the frame will be made of 8" square oak pillars and 6" square beams, and a proper tile roof, I settled on 2 foot cube pads per pillar - 6,nr.

So, much digging though nothing but completely lovely top soil -

Then I came up with a design for a reinforcing cage made from 6mm and tied with metal gardening twine / cable ties:

Made a one off:

And fired up the xmas gin

Then made a production line, all hand bend over the stone wall outside (wheey)

Finished them quite late, was wobbly by this point

So made coq au vin, properly wobbly by this point

My parents have a few acres in France and I've ran out of activities to do outside of drinking the local wine - its Lot-et-Garrone region which is all thick full bodied Bordeaux style and I can't handle it any more.

So they also have an oak forest intruding onto the property meaning there is plenty of 10+"diameter x 40 foot oaks ion the garden, and most of them are nicely straight & true.

So I decided to make something from oak, something like a gable end garage a bit like this:

As usual with any of my projects I set about doing the whole thing completely free, as, being an engineer, I refuse to pay for engineering services by others.. (mostly)

Did some working out of materials and sizes:

Decided the joints where 3-4 beams converge was not practical with my skill, so figured out a work around using simple steel designs

Bit more detail design;

Thinking all the steel will be premade in UK and shipped over, so figured just make one size of strapping and pack the smaller beams to suit

Basically decided to copy the roman wash house down the road because it looks nice. We are also near a 14th century church and to comply with / and achieve any kind of consent, any new building needs to look like it basically, and as I will be building a 'wood store' first (no walls), then go down the retrospective planning route and asking for permission to wall it in, as we assume the local council will actually be impressed by it..

After reading in to what's easiest and/or best to do for foundations (strip or raft), I decided to go for pad foundations... As I decided the frame will be made of 8" square oak pillars and 6" square beams, and a proper tile roof, I settled on 2 foot cube pads per pillar - 6,nr.

So, much digging though nothing but completely lovely top soil -

Then I came up with a design for a reinforcing cage made from 6mm and tied with metal gardening twine / cable ties:

Made a one off:

And fired up the xmas gin

Then made a production line, all hand bend over the stone wall outside (wheey)

Finished them quite late, was wobbly by this point

So made coq au vin, properly wobbly by this point