Hello,

We have a new roof, with new frames, new tiles and new velux windows (all 1 year old now).

We have done most things right on our project, however one decision that i am REALLY not happy with is the size of our Velux windows.

We currently have 550x1200 top hung Velux windows, which are quite small.

I want to rip out these windows are replace with 940 x 1400 or 940 x 1600 velux.

Our roof trusses are at 600mm centes and so no trusses were cur for the current windows, but a single top section of truss would need to be cut for the new windows.

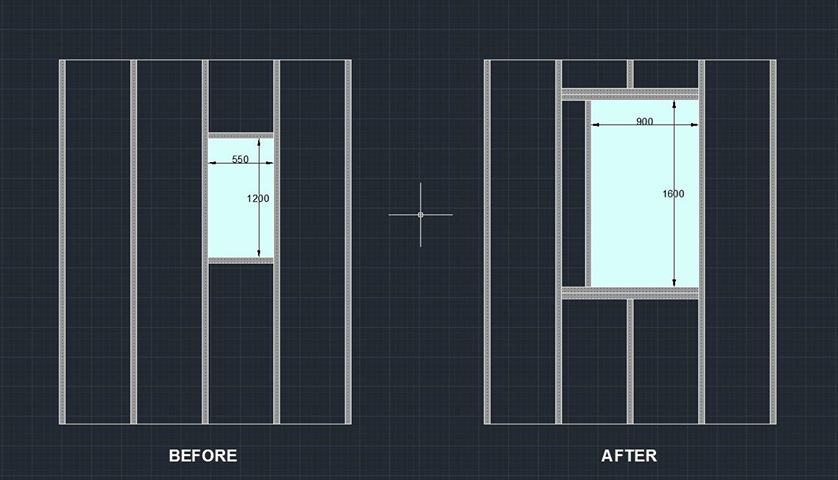

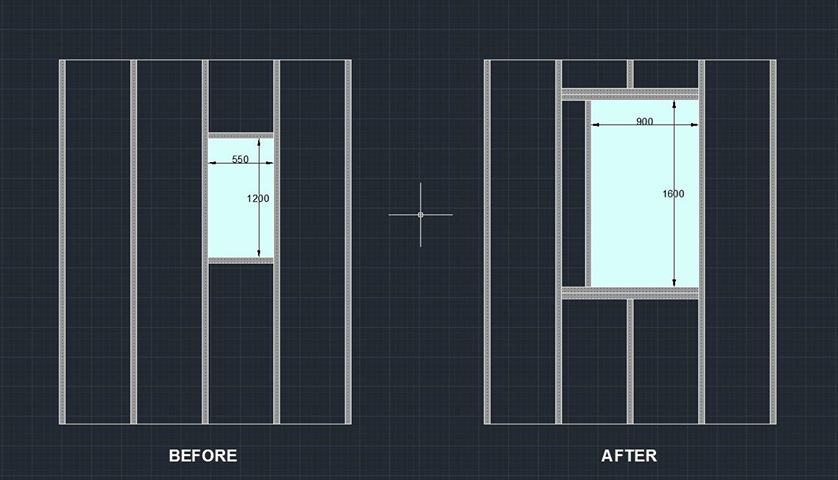

Here is a plan for what i want to do:

(Diagram shows face on view of slopes of roof trusses with timbers of 47 x 175mm)

I would normally double up the trusses either side of the window. However, we have VERY heavy duty timbers of 47 x 175mm supporting the roof tiles and 47 x 225 across the bottom string (floor). Also, we are using light weight Roof tiles at a weight of 20kg per square metre, but our roof trusses were designed for tiles that are 60+ kg per square metre.

So overall of roof trusses are over engineered and so i do not think that i need to use a double either side of the new velux. As the TOTAL load of roof components (tiles + top of truss + lats) above each window is only 70kg.

However i have incorporated double horizontal timbers above and below the new velux to support this 70kg and spread the load side ways to the other two trusses.

- My plan is to remove the current window and strip away a large amount of tiles etc.

- Remove the existing flashing and window frame.

- Put up acroprops and bolt in temp timbers bracing across three timbers to support the one timber that is going to be cut.

- Cut the middle timber vertical.

- Then to install the new timber horizontal pieces (47 x 175) using structural bolts/screws and steel brackets.

- Then put in the new offset timber vertical pieces to the new windows size.

- Then install the new window frame and sort out the lats, felt, flashing and tiles.

- Then sort out the inside again including a bit of OSB and some insulation.

- Then slot the new window into it's frame.

- Remove temp supports and acroprops

But what do people think?

Thanks

We have a new roof, with new frames, new tiles and new velux windows (all 1 year old now).

We have done most things right on our project, however one decision that i am REALLY not happy with is the size of our Velux windows.

We currently have 550x1200 top hung Velux windows, which are quite small.

I want to rip out these windows are replace with 940 x 1400 or 940 x 1600 velux.

Our roof trusses are at 600mm centes and so no trusses were cur for the current windows, but a single top section of truss would need to be cut for the new windows.

Here is a plan for what i want to do:

(Diagram shows face on view of slopes of roof trusses with timbers of 47 x 175mm)

I would normally double up the trusses either side of the window. However, we have VERY heavy duty timbers of 47 x 175mm supporting the roof tiles and 47 x 225 across the bottom string (floor). Also, we are using light weight Roof tiles at a weight of 20kg per square metre, but our roof trusses were designed for tiles that are 60+ kg per square metre.

So overall of roof trusses are over engineered and so i do not think that i need to use a double either side of the new velux. As the TOTAL load of roof components (tiles + top of truss + lats) above each window is only 70kg.

However i have incorporated double horizontal timbers above and below the new velux to support this 70kg and spread the load side ways to the other two trusses.

- My plan is to remove the current window and strip away a large amount of tiles etc.

- Remove the existing flashing and window frame.

- Put up acroprops and bolt in temp timbers bracing across three timbers to support the one timber that is going to be cut.

- Cut the middle timber vertical.

- Then to install the new timber horizontal pieces (47 x 175) using structural bolts/screws and steel brackets.

- Then put in the new offset timber vertical pieces to the new windows size.

- Then install the new window frame and sort out the lats, felt, flashing and tiles.

- Then sort out the inside again including a bit of OSB and some insulation.

- Then slot the new window into it's frame.

- Remove temp supports and acroprops

But what do people think?

Thanks

Last edited: