Just had the original Welsh slate removed, felt and new battens. The original slate and additional reclaimed slates laid.

Called the roofer back as the eaves didn't look right and a gap is now evident behind barge boards.

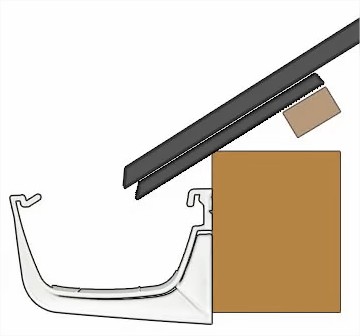

Gaps under slates on eaves.

Gap behind fascia board (that's an old fillet behind the plastic lying on the rafter in the gap)

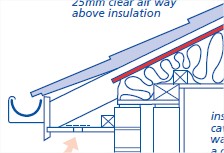

Now 'fixed', does this look okay?

Eaves at the other end of the roof.

Opinions and advice appreciated.

Called the roofer back as the eaves didn't look right and a gap is now evident behind barge boards.

Gaps under slates on eaves.

Gap behind fascia board (that's an old fillet behind the plastic lying on the rafter in the gap)

Now 'fixed', does this look okay?

Eaves at the other end of the roof.

Opinions and advice appreciated.

Last edited: