Attached is a ground floor picture of the soil pipe in our home. There was originally a toilet which has now been permanently capped off and you can also see a sink waste pipe attached.

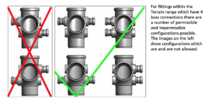

My plan is to drill out one of the 50mm sockets directly opposite the current sink waste for a new 40mm shower waste pipe, attached with a Marley Push-Fit connector (the same as pictured for sink) but I've just discovered that this would be discouraged due to potential "crossflow" with the sink opposite.

I want to check would crossflow still be a problem in this case given it's a sink/shower so no solid waste flow from those pipes, nothing to block the opposite pipe. Both pipes would be slightly angled as you'd expect and the sink has quite a sharp downwards drop so I can't see how either would cause a large flow of water up the opposite pipe but I may be wrong.

I definitely don't want to be replacing any part of the stack so would it be better to fit the shower waste opposite, move the sink waste up to the socket above where it currently is and cap off the existing sink socket? Or is this all overkill and just go opposite with the shower anyway? There is also another toilet waste near the opposite wall, worst case I can route the sink waste under the cabinets to there if the above is a terrible idea. I'm unable to use the old toilet connection as all of this is being boxed in to the adjacent cabinet depth so I wouldn't have space for a pipe there.

The second screenshot seems to indicate I should just go opposite and NOT staggered.

All much easier with the walls down so want to get it right now, thanks!

My plan is to drill out one of the 50mm sockets directly opposite the current sink waste for a new 40mm shower waste pipe, attached with a Marley Push-Fit connector (the same as pictured for sink) but I've just discovered that this would be discouraged due to potential "crossflow" with the sink opposite.

I want to check would crossflow still be a problem in this case given it's a sink/shower so no solid waste flow from those pipes, nothing to block the opposite pipe. Both pipes would be slightly angled as you'd expect and the sink has quite a sharp downwards drop so I can't see how either would cause a large flow of water up the opposite pipe but I may be wrong.

I definitely don't want to be replacing any part of the stack so would it be better to fit the shower waste opposite, move the sink waste up to the socket above where it currently is and cap off the existing sink socket? Or is this all overkill and just go opposite with the shower anyway? There is also another toilet waste near the opposite wall, worst case I can route the sink waste under the cabinets to there if the above is a terrible idea. I'm unable to use the old toilet connection as all of this is being boxed in to the adjacent cabinet depth so I wouldn't have space for a pipe there.

The second screenshot seems to indicate I should just go opposite and NOT staggered.

All much easier with the walls down so want to get it right now, thanks!

Attachments

Last edited: