- Joined

- 17 Apr 2007

- Messages

- 2,524

- Reaction score

- 127

- Country

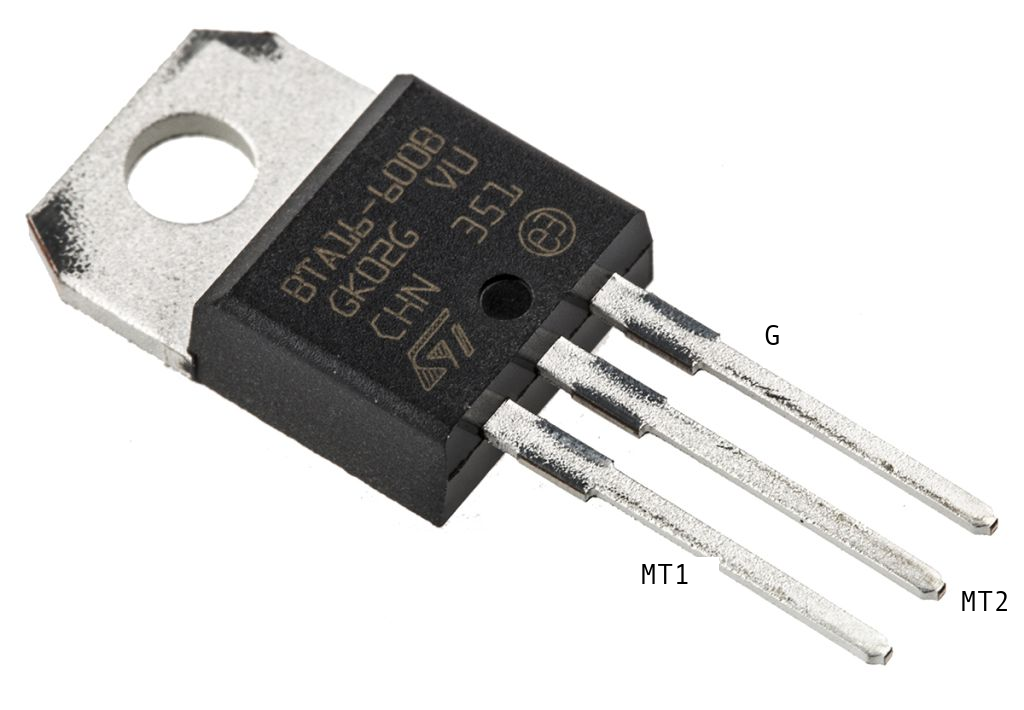

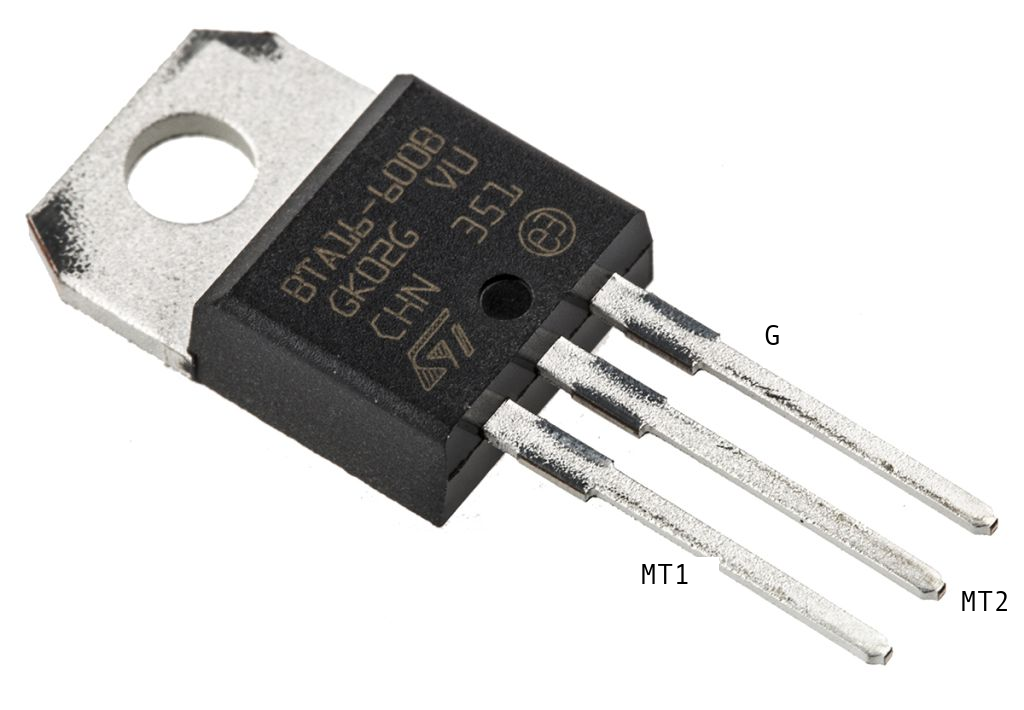

The triac sits in the pcb control board of a Bosch Classicx 1400 washing machine. The image I've attached is merely to show the terminals, the part no for mine is BTB16 600CW.

I've watched a number of videos on YT about testing them but its confusing.

With the multimeter set to Ω, there should be a reading between and MT1 and G terminals.

Between MT1 and MT2 there should be open circuit until MT2 and G are bridged but to my mind that's only allowing MT1 and G to make circuit and doesn't confirm that MT1 and MT2 are connecting to make circuit.

Can anyone clarify for me please?

I've watched a number of videos on YT about testing them but its confusing.

With the multimeter set to Ω, there should be a reading between and MT1 and G terminals.

Between MT1 and MT2 there should be open circuit until MT2 and G are bridged but to my mind that's only allowing MT1 and G to make circuit and doesn't confirm that MT1 and MT2 are connecting to make circuit.

Can anyone clarify for me please?