- Joined

- 13 Jul 2024

- Messages

- 20

- Reaction score

- 0

- Country

Hi There,

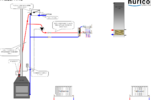

I have an issue where a pump is constantly cavitating on a central heating system. Please see screenshot of installed schematic.

The system is new and installed as per the schematic supplied by the designer. All lines where bled as well as the pump.

The height between the top of the water in the header tank and the pump is approx 0.5m, so there is a small amount of static at the inlet to the pump.

Any suggestions?

Thank you

Nathan

I have an issue where a pump is constantly cavitating on a central heating system. Please see screenshot of installed schematic.

The system is new and installed as per the schematic supplied by the designer. All lines where bled as well as the pump.

The height between the top of the water in the header tank and the pump is approx 0.5m, so there is a small amount of static at the inlet to the pump.

Any suggestions?

Thank you

Nathan