I took it that Nathan was referring to the original layout. I suppose he could just modify it as per his post 24 schematic (below) which takes very little work, if only to prove the point that it will cure the cavitation, he can then decide to go the full hog or not.That was on the original layout, with cold feed to the boiler return. We hope to have cured it with the revised layout.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cavitation on Rayburn Central Heating

- Thread starter nathan_b_a

- Start date

- Joined

- 13 Jul 2024

- Messages

- 20

- Reaction score

- 0

- Country

Hi Fixitflav,

I meant the static head to the Harworth heating schematic that Jon posted in #31.

The F& E tank in my system is above the pump in the loft. I can set it up so it is about 1m above the pump inlet (As per my drawing in #42)

The injector tee is a device that has a venturi in it that draws water through one part of the tee. In this case (i.e., drawing #42), the injector tee, when the pump is running, draws water through the DHW tank so that flow is always maintained through that circuit and not exclusively through the radiators

I meant the static head to the Harworth heating schematic that Jon posted in #31.

The F& E tank in my system is above the pump in the loft. I can set it up so it is about 1m above the pump inlet (As per my drawing in #42)

The injector tee is a device that has a venturi in it that draws water through one part of the tee. In this case (i.e., drawing #42), the injector tee, when the pump is running, draws water through the DHW tank so that flow is always maintained through that circuit and not exclusively through the radiators

- Joined

- 13 Jul 2024

- Messages

- 20

- Reaction score

- 0

- Country

Hi Jon,

In the current original problematic setup (ie where the cavitating pump supplies a manifold which in turn supplies radiators and the DHW tank), the pipe ID size from manifold to radiators and DHW tank is probably around 1/2 inch.

If I understand correctly, you suggest having the DHW tank on the primary thermosiphon circuit (i,e., my #42 circuit) but with the knowledge that the thermosiphon effect for the DHW tank will be smaller than the pumped circuit through the manifold (i.e., my #24 circuit). My pipe run from stove to tank is pretty good in terms of steepness and pipes insulated and there are not really any horizontal runs so the thermosiphon part is as good as it will get.

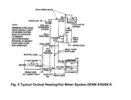

It seems that Rayburn and other wood stove manufactures seem to recommend the circuit similar designs to what was posted in #31. That design would seem to be contrary to the advice in post #20 regarding the optimum position for pumps and could lead to pumping over.

In the current original problematic setup (ie where the cavitating pump supplies a manifold which in turn supplies radiators and the DHW tank), the pipe ID size from manifold to radiators and DHW tank is probably around 1/2 inch.

If I understand correctly, you suggest having the DHW tank on the primary thermosiphon circuit (i,e., my #42 circuit) but with the knowledge that the thermosiphon effect for the DHW tank will be smaller than the pumped circuit through the manifold (i.e., my #24 circuit). My pipe run from stove to tank is pretty good in terms of steepness and pipes insulated and there are not really any horizontal runs so the thermosiphon part is as good as it will get.

It seems that Rayburn and other wood stove manufactures seem to recommend the circuit similar designs to what was posted in #31. That design would seem to be contrary to the advice in post #20 regarding the optimum position for pumps and could lead to pumping over.

For gravity circulation, the cylinder pipes should be 22mm but even as is and with the rads also in loop, if the vent is extented up and over the F&E cistern and if the cold feed is teed in just after the vent then that should allow some gravity circulation and there is still the safety of having the now open vent which will prevent pressure build up in the cylinder, schematic in post#31 is the definitive installation, post #20 schematic just shows that the cold feed should be after the vent, that system is very common in a fully pumped system but I would venture that in almost all gravity systems the pump is located low down on the return, thats why it might be prudent just to modify the vent and cold feed just now because if you get pump over into the F&E cistern (with the circ pump on) then you migh have to relocate the pump, but hopefully not. If no pump over you can then decide your next step.Hi Jon,

In the current original problematic setup (ie where the cavitating pump supplies a manifold which in turn supplies radiators and the DHW tank), the pipe ID size from manifold to radiators and DHW tank is probably around 1/2 inch.

If I understand correctly, you suggest having the DHW tank on the primary thermosiphon circuit (i,e., my #42 circuit) but with the knowledge that the thermosiphon effect for the DHW tank will be smaller than the pumped circuit through the manifold (i.e., my #24 circuit). My pipe run from stove to tank is pretty good in terms of steepness and pipes insulated and there are not really any horizontal runs so the thermosiphon part is as good as it will get.

It seems that Rayburn and other wood stove manufactures seem to recommend the circuit similar designs to what was posted in #31. That design would seem to be contrary to the advice in post #20 regarding the optimum position for pumps and could lead to pumping over.

The static head on the pump inlet is just the height between the pump inlet and the F/E tank water level. From the heights you've given that's ~ 3 - 4 m if the pump is low down on the boiler return as on Haworth. The dynamic head, on that arrangement, at pump inlet is lower due to headloss in the boiler, rads and pipework. On the face of it that doesn't seem a good arrangement, it's like Pump position 1 in Johntheo5's #20. But I suppose Haworth know what they're doing, as I said, it's not my field.I meant the static head to the Harworth heating schematic that Jon posted in #31.

But I don't suppose you're going for the full Haworth, that would be a major change.

That should be fine, it's better than the 0.5 m earlier. But it's not the Haworth set-up.The F& E tank in my system is above the pump in the loft. I can set it up so it is about 1m above the pump inlet (As per my drawing in #42)

OK thanks. It has occurred to me that on a gravity HW, pumped rads system (common till about the 1980s), when the pump runs there could be a reverse flow through the HW cylinder, in the bottom connection, out the top. The injector tee should stop it happening on Haworth.The injector tee is a device that has a venturi in it that draws water through one part of the tee. In this case (i.e., drawing #42), the injector tee, when the pump is running, draws water through the DHW tank so that flow is always maintained through that circuit and not exclusively through the radiators

Talking generally about the much vaunted VCP system, I've read numerous posts where there was pump over (especially during starting and stopping of the circ pump) even on apparently perfectly installed systems and on some where the section of the vent and cold feed was cut out and replaced in case of blockages which will cause this, a number of people converted to a combined vent and cold feed and the problems disappeared.

150mm of 22mm pipng should still only have a head loss of ~ 0.02M (20mm) at a flowrate of 25LPM so the level in the vent should only rise by this amount, someone (with no problems) had a camera/device that could detect the water level in vertical pipes and confirmed that the vent pipe level was only ~ 15mm (0.015M) higher than the F&E cistern level.

150mm of 22mm pipng should still only have a head loss of ~ 0.02M (20mm) at a flowrate of 25LPM so the level in the vent should only rise by this amount, someone (with no problems) had a camera/device that could detect the water level in vertical pipes and confirmed that the vent pipe level was only ~ 15mm (0.015M) higher than the F&E cistern level.

I'd still be interested in the designer's comments on this. One thing is - is it OK to have no heat sink rad in addition to trhe HW cylinder?

A very good point re heat leak radiator we would never install a central heating solid fuel cooker without one.I'd still be interested in the designer's comments on this. One thing is - is it OK to have no heat sink rad in addition to trhe HW cylinder?

I'm certainly not keen on dipped cold feeds on close coupled feed and vent set ups either , on systems with a steel heat exchanger they can block very quickly.

Harworthyheating advise "In case of electrical failure it is essential to allow at least 25% - 30% of the boiler output, to be available as a form of gravity heat leak. This can be achieved by fitting radiators teed off the primary circuit, as illustrated in the diagram." wonder what that will achieve overall, a fairly modest output of say 10kw means 7kw must still be dealt by some other means, I suppose the boiler will not normally be outputting 100% so 30% is a help. Theoretically, the easiest way of all is to let it generate steam, a boiler at say 75% efficiency will generate ~ 10.0kgs/hour at 10.0kw output and only requires cold water make up of 0.17LPM, the trick is to get rid of the steam from the attic. I think on the continent where pressurized solid fuel systemas are allowed that they run cold water from a header tank through another heat exchanger in the boiler in the event of power or pump failure.A very good point re heat leak radiator we would never install a central heating solid fuel cooker without one.

I'm certainly not keen on dipped cold feeds on close coupled feed and vent set ups either , on systems with a steel heat exchanger they can block very quickly.

- Joined

- 13 Jul 2024

- Messages

- 20

- Reaction score

- 0

- Country

There is some reinventing the wheel here!Hi @Exedon

Presumably the alternative to a dipped cold feed is to have it connected directly, vertically, but then the downside is heat can rise up the cold feed pipe and heat the header tank. Do you think the diagram in #42 will work aside from that? I can add in a heat leak radiator.

The standard layout is used because it works.

Solid fuel = gravity primarys injector tee (we made our own) and correctly sized heat leak rad.

I personally think the dipped cold feed is just asking for trouble , at end of day of cause water will expand up it that's what it does! dipped or not.

Assuming by dipped cold feed you mean under and up, I can't agree with that. Expansion, and slight change in levels in the vent and feed pipes can't be avoided, but convection in the feed pipe can. And why is it worse with a steel heat exchanger? The system should have inhibitor whatever the mterials. I installed mine with under and up ~ 25 years ago and it's been fine.I personally think the dipped cold feed is just asking for trouble , at end of day of cause water will expand up it that's what it does! dipped or not.

Edit - and there's much greater steel surface in the rads than in the boiler heat exchanger.

Last edited:

I'm afraid one install means nothing you have probably got a clean system most are not .

Large steel heat exchanger open vent = corrosion most people don't top up inhibitor but do regularly vent rads.

Crap mostly metallic gathers in u section very easily, happens on a normal H section as well but generally slower.

I can assure you water goes up cold feed every time boiler runs where do you think the water expands to?

Large steel heat exchanger open vent = corrosion most people don't top up inhibitor but do regularly vent rads.

Crap mostly metallic gathers in u section very easily, happens on a normal H section as well but generally slower.

I can assure you water goes up cold feed every time boiler runs where do you think the water expands to?

Last edited:

It's not just my set-up, it's recommended by boiler manufacturers.I'm afraid one install means nothing you have probably got a clean system most are not .

Do any boilers have carbon steel heat exchamgers nowadays? All the data I see says aluminium or stainless, with occasional cast iron.Large steel heat exchanger open vent = corrosion most people don't top up inhibitor but do regularly vent rads.

My first house in 1972 had a CH 501 boiler with steel H/Ex (recognised as cheap and cheerful even then!) but I don't know of any since. It was also plumbed with cold feed on boiler return, which risks corrosion due to see-sawing. I changed it to BVCP.

That's not desirable, but it's blockage between the vent and cold feed which will cause overpumping.Crap mostly metallic gathers in u section very easily happens on a normal H section as well but generally slower.

I covered that in #57I can assure you water goes up cold feed every time boiler runs where do you think the water expands to?

Shouldn't we be encouraging users to maintain their system properly, not install an inferior system because it's more tolerant to abuse?

- Joined

- 13 Jul 2024

- Messages

- 20

- Reaction score

- 0

- Country