look at the kerf thickness and riving knife on the saw

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help me choose a table saw blade for gloss kitchen doors

- Thread starter aveatry

- Start date

I am not sure of the riving knife that the dewalt has as I do not have it yet - waiting for a good black friday offer, or it may even have two sizes of riving blade with it.look at the kerf thickness and riving knife on the saw

So am I correct in thinking that the saw blade kerf should be less than the riving blade thickness

as far as i'm aware and google search

The riving knife must be thicker than the plate of the saw but less than the kerf (thickness of cut).

the spec on dewalt is not great ....

The riving knife must be thicker than the plate of the saw but less than the kerf (thickness of cut).

the spec on dewalt is not great ....

just get the ultra thin kerf blade from dewalt they are brilliant i used to use only freid pro then changed to dewalt and when i needed a one off for my dw712 without the bulking out the order for free postage i chose a green saxton blade and was ultra ultra impressed 2x1 timber it cut so easilly and cleanly it was as iff the wood wasnt there no tone change or cutting noise no resistance

and the 2 wriving knives are the same one has a blade gaurd fitted the other is a fraction below the blade so you can do flip cuts to cut the other half the thickness without catching the knife

and the 2 wriving knives are the same one has a blade gaurd fitted the other is a fraction below the blade so you can do flip cuts to cut the other half the thickness without catching the knife

I removed the riving knife from my saw years ago. It is an old Festool TS55 plunge saw. I was doing some cutouts so I had to remove it (their newer saws have a riving knife that retracts as required).

The only time that my saw ever sees real timber is when trimming door edges, and a 5mm strip of softwood is unlikely to grab the blade.

The only time that my saw ever sees real timber is when trimming door edges, and a 5mm strip of softwood is unlikely to grab the blade.

- Joined

- 25 Apr 2016

- Messages

- 2,531

- Reaction score

- 582

- Country

I'd say a 40 or 48 tooth blade is a good compromise. More teeth means that you have to be careful not to burn the material you are cutting by going to slow and overloading the machine by going to fast.

I'll agree with putting (good quality) masking tape on the cut line - both sides.

Set the blade height so only half of the highest tooth is visible through the material you are cutting - with the Face side up.

I'll agree with putting (good quality) masking tape on the cut line - both sides.

Set the blade height so only half of the highest tooth is visible through the material you are cutting - with the Face side up.

Thanks for the info I wasnt sure if the dewalt came with the 2 riving blades and if it did if they were different. Sounds like a saxton may be a good bet.just get the ultra thin kerf blade from dewalt they are brilliant i used to use only freid pro then changed to dewalt and when i needed a one off for my dw712 without the bulking out the order for free postage i chose a green saxton blade and was ultra ultra impressed 2x1 timber it cut so easilly and cleanly it was as iff the wood wasnt there no tone change or cutting noise no resistance

and the 2 wriving knives are the same one has a blade gaurd fitted the other is a fraction below the blade so you can do flip cuts to cut the other half the thickness without catching the knife

Masking tape - got it. I see what you mean about tooth count a 48 may be the way to go.I'd say a 40 or 48 tooth blade is a good compromise. More teeth means that you have to be careful not to burn the material you are cutting by going to slow and overloading the machine by going to fast.

I'll agree with putting (good quality) masking tape on the cut line - both sides.

Set the blade height so only half of the highest tooth is visible through the material you are cutting - with the Face side up.

I use my Festool TS75 with a Festool special laminate blade. Expensive, but incredible finish. https://ffx.co.uk/product/Get/Festo...-Special-Saw-Blade--190Mm-X-30Mm-Tf54-54Teeth

i will fully agree with a 48 tooth as a compromise over a 60 tooth as the 60 tooth is the best possible finish but at extra load a bit slower cut i have several blades so pick the blade for the jobMasking tape - got it. I see what you mean about tooth count a 48 may be the way to go.

24 will be the best compromise as a rip saw but at the crude/a bit rough end for cross cutting 48 is over the top for most rip cuts but good for crosscuts and boards 60 is heavy on rip but smooth on boards

as an aside cross cut across the grain rip is along the grain

I use my Festool TS75 with a Festool special laminate blade. Expensive, but incredible finish. https://ffx.co.uk/product/Get/Festo...-Special-Saw-Blade--190Mm-X-30Mm-Tf54-54Teeth

What is the longevity of the blade like when cutting laminate? That is a clumsy way of asking if it will stay sharper than the blade supplied with the saw at the point of purchase?

I only lay laminate floors, on average about every 4(?) years. The last one was for a mate. I used my Festool jigsaw (with the chip insert) for most of the long cuts, but on Sundays I used a brand new Japanese saw. After 2 rooms and a hallway, I now have a very blunt £30 Japanese saw...

Thanks everyone I have been trying to work out which way the grain goes on my chipboard furniture sheets.

Dewalt saw ordered on a black Friday deal and I have just received a set of 2 blades from saxton, a 40 and a 60 tooth. The kerf is stated on the saxton website at 2.4mm but not the blade thickness so I measured it to be1.7 or 1.8 or 1.9 (had trouble as the battery is about dead in my gauge.) is under 2 though.

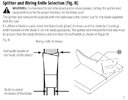

I also got this from the PDF of the dewalt instructions.

English

8

OPERATION

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect it from power source before making any adjustments or removing/installing attachments or accessories. An accidental start-up can cause injury.

The riving knife provided with this saw is marked as follows:

.087” (2.2 mm) THICK RIVING KNIFE. ONLY FOR USE WITH 8-1/4” (210 mm) BLADE WITH .094” (2.4 mm) MIN KERF WIDTH AND .079” (2.0 mm) MAX BODY THICKNESS.

Blade body thickness and kerf width dimensions for all DeWALT table saw blades are available at www.dewalt.com

If a different blade is used and the body thickness and kerf width dimensions are not provided, use the following procedure to determine the correct riving knife thickness:

1.

Measure the body thickness of the blade.

2.

Make a shallow cut in scrap material and measure the kerf width.

3.

Select the riving knife 21 .

4.

Slide the riving knife through the shallow cut made in step 2 to confirm the correct riving knife has been selected. The riving knife should not bind or drag through the cut.

WARNING: If any dragging or binding of the material is encountered as it reaches the riving knife, turn unit off and disconnect machine from power source. Repeat steps 1–4 to make the proper riving knife selection before attempting another cut.

Dewalt saw ordered on a black Friday deal and I have just received a set of 2 blades from saxton, a 40 and a 60 tooth. The kerf is stated on the saxton website at 2.4mm but not the blade thickness so I measured it to be1.7 or 1.8 or 1.9 (had trouble as the battery is about dead in my gauge.) is under 2 though.

I also got this from the PDF of the dewalt instructions.

English

8

OPERATION

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect it from power source before making any adjustments or removing/installing attachments or accessories. An accidental start-up can cause injury.

The riving knife provided with this saw is marked as follows:

.087” (2.2 mm) THICK RIVING KNIFE. ONLY FOR USE WITH 8-1/4” (210 mm) BLADE WITH .094” (2.4 mm) MIN KERF WIDTH AND .079” (2.0 mm) MAX BODY THICKNESS.

Blade body thickness and kerf width dimensions for all DeWALT table saw blades are available at www.dewalt.com

If a different blade is used and the body thickness and kerf width dimensions are not provided, use the following procedure to determine the correct riving knife thickness:

1.

Measure the body thickness of the blade.

2.

Make a shallow cut in scrap material and measure the kerf width.

3.

Select the riving knife 21 .

4.

Slide the riving knife through the shallow cut made in step 2 to confirm the correct riving knife has been selected. The riving knife should not bind or drag through the cut.

WARNING: If any dragging or binding of the material is encountered as it reaches the riving knife, turn unit off and disconnect machine from power source. Repeat steps 1–4 to make the proper riving knife selection before attempting another cut.